The modern industrial age is completely dependent on metal. Indeed, it’s easy to think of hundreds of uses for metal. Due to this, it can be fascinating to explore how these metal products and structures are actually created. This occurs through metal fabrication.

Industries That Use Metal Fabrication

From agriculture to electronics, many industries rely on metal fabrication for the production of durable, high quality and efficient metal components.

- Automotive

- Aerospace

- Agricultural

- Electronics

- Medical

If you want to outsource your production to a bespoke fabrication specialist, look no further than Wrekin Sheetmetal. We provide comprehensive fabrication services tailored to meet the specific requirements of your industry.

What Are The Types Of Metal Fabrication?

The sheet metal fabrication process does not refer to one process. Instead, it is an umbrella term which includes various core processes.

Cutting

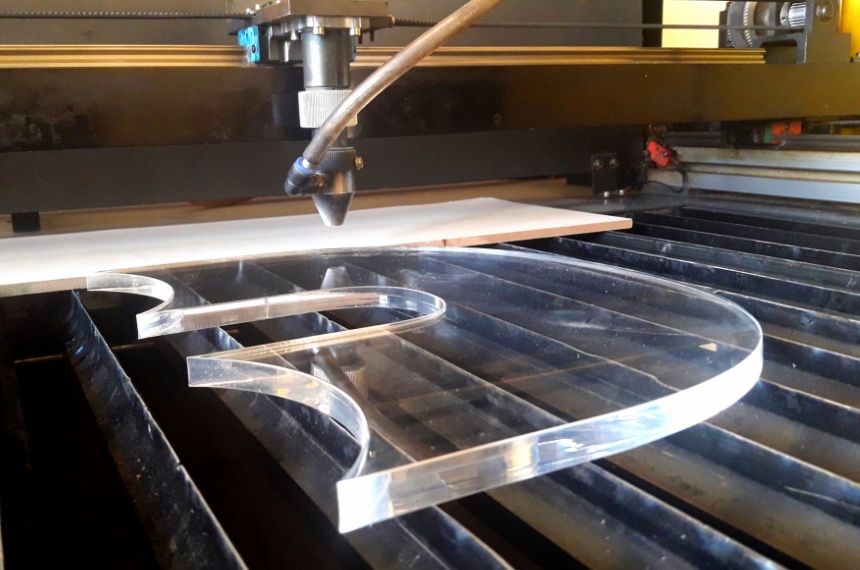

There are many different cutting methods that can be used, some of which are done manually, while others are completed by cnc cutters. Some of the types of cutting include:

- Laser cutting

- Use of water jets

- Power scissors

- Plasma

Cutting is an important part of the metal fabrication process as it is how the sheet metal is taken from one size to another. A sheet of metal might need to be cut for a variety of reasons. For example, it may be too big for the intended use. This can be done at any point throughout the metal fabrication process, but is usually completed at the beginning, with further cutting being completed when necessary.

Punching

Punching is a metal fabrication method that involves a tool known as a punch die being forced through a piece of sheet metal to create a hole. Punching can be used to cut out holes and shapes of various sizes, making it essential to the metal fabrication process overall.

Stamping

Stamping is a process in metal fabrication that involves creating indentations or imprints on the workpiece.

The process involves applying pressure to a die and forcing it into the metal, forming the desired shape. It is an efficient and cost-effective, allowing for the mass production of intricate metal components with high precision and accuracy.

Welding

Welding refers to the process of connecting or adjoining two pieces of metal. In some cases it can include more than two pieces. This is achieved through the use of pressure and heat.

The process isn’t used in every type of metal manufacturing. Instead, it’s more common for industrial or large scale fabrication processes. At Wrekin Sheet Metal, we used a variety of welding procedures including:

- Mig Welding

- Tig Welding

- Spot Welding

These vary in terms of the steps and equipment that are used to complete the welding process. They are also some of the most common options for welding metal. Welding can be suitable for a variety of metal types including different sizes and shapes.

Extrusion

Extrusion is a highly efficient metal fabrication technique that shapes solid billets of alloy or metal into beams and sectional components. It involves passing the billet through a tooling die using a high-powered hydraulic and high-pressure system.

This process is commonly used in the production of steel or aluminium beams and sectional components.

Forming

Forming is primarily done in hot working conditions so that you can shape metal with ease. Forming refers to the process of bending the metal to the required angle. This can be useful in the creation of a range of metal products and even the supplies that are used to create the skeleton of buildings. It is usually completed with a brake press to provide pressure so that a required crease is effectively formed.

Casting

Casting involves heating a metal until its melting point and pouring it into a mould.

This method allows for the creation of complicated shapes in a single run. However, careful casting operations are needed to prevent cracks and damage caused by internal stresses during the heating and cooling process.

Forging

Forging is one of the oldest and most reliable metal fabricating techniques, using compression forces to shape, bend, or press the metal into various sizes. It's a reliable method used in various industries and applications.

There are different forging techniques such as cold forging, hot forging, and open die forging.

We hope this helps you understand the metal fabrication process and the different core elements. If you need an expert metal fabrication service, please do not hesitate to contact our team at Wrekin Sheet Metal today. We’re ready to assist you with all your needs.

How can we help?

With over 17+ years of knowledge and experience, we’re confident we can offer a flexible solution beneficial to both parties, get in touch with us today.