The UKs Leading sheet metal

Fabrication &

Assembly Specialist

The Wrekin Approach

Built Around Reliability, Not Just Capacity since 2003.

Wrekin Sheetmetal was built to solve a common problem in manufacturing: reliable sheet metal supply that doesn’t require constant chasing.

Alongside significant investment in automation, our focus remains on what matters most to customers: delivery certainty with expected quality, clear communication, and accountability.

We work with manufacturers who need a dependable partner they can trust to keep production moving, respond quickly when designs change, and take ownership when challenges arise.

We offer a supportive, end-to-end service, taking initial concepts from consultation, through to assembly & delivery,

producing high quality, precise sheet metal fabrication solutions, backed up by over 20 years of experience.

Our Capabilities

We provide a complete in-house sheet metal manufacturing service, allowing customers to consolidate suppliers and maintain quality control throughout the process.

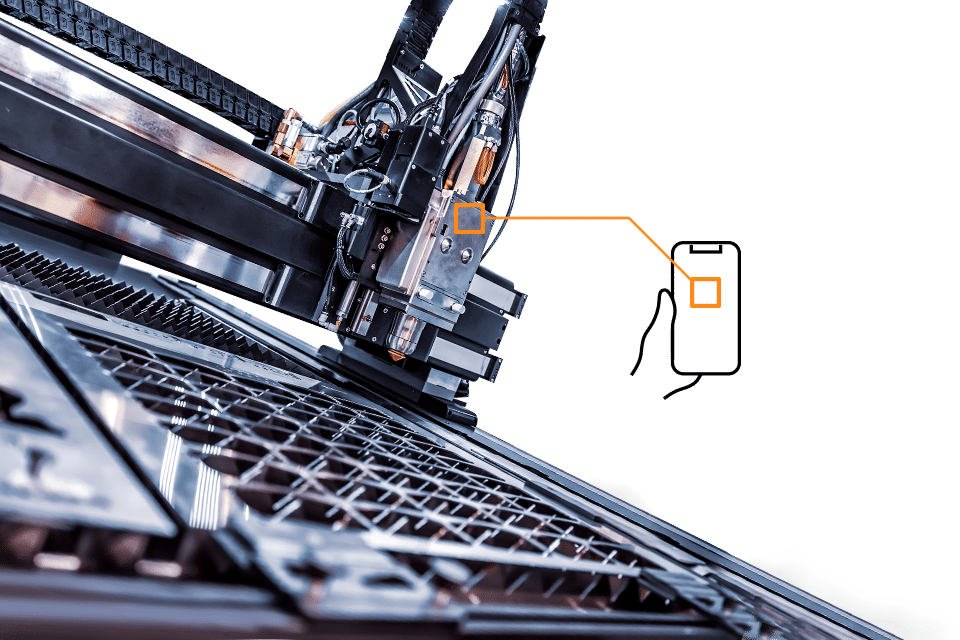

Laser Cutting

High-precision laser cutting for a wide range of metals, delivering consistent accuracy across prototypes, batch work, and repeat production.

Sheet Metal Fabrication

Comprehensive fabrication services including forming, folding, and CNC press brake work, suitable for both complex and high-volume components.

Welding & Assembly

Skilled welding and assembly services, supporting structural and precision applications, with a focus on strength, repeatability, and finish.

Powder Coating

By managing the coating process internally, we maintain full control over quality, lead times, and consistency, removing the risks and delays associated with third-party finishing.

Contract & Repeat Manufacturing

We specialise in supporting OEMs with ongoing production, offering reliable capacity, structured processes, and consistency across repeat orders.

Talk to Our Team

OEM manufacturing enquiries are welcome.

We've invested in our staff and equipment

since 2003

Enabling us to bring you the most up to date sheet metal fabrication capabilities back up by over

20+ years of experience, by people who care!

Most of our employees have been with us from the start, growing with us into the Wrekin family

we’re so proud of today!

Engineering Software & Digital Manufacturing

Wrekin Sheetmetal operates within a digitally connected engineering and manufacturing environment, ensuring accuracy, control, and repeatability from design through to production.

Our engineering team uses SolidWorks for 3D design and design-for-manufacture support, allowing us to work directly with customer models, assess manufacturability, and manage controlled design changes.

Manufacturing data is transferred into RADAN, where components are programmed, nested, and prepared for production using accurate, software-driven workflows. This ensures consistency between design intent and manufactured parts, while supporting efficient material usage and repeatable results.

To support structured production planning and repeat manufacturing, we utilise EasyBOM to manage bills of materials and component structures, ensuring accurate job breakdown, traceability, and control across assemblies and batch production.

Together, these systems form an integrated digital workflow that supports ISO 9001:2015-aligned process control, reduces risk, and enables reliable delivery for OEM and manufacturing customers.