What Materials Can Be Laser Cut?

Discover the versatility of laser cutting with a range of materials from metals like steel and aluminium to leather, acrylic, wood, and paper. Each material offers unique benefits and challenges, ensuring precision and creativity in your projects.

The Top Benefits Of Quality Control In Metal Fabrication

Implementing quality control in metal fabrication ensures precise, reliable products and improves manufacturing efficiency. This process enhances customer relationships, safety, and compliance with industry standards, while also reducing costs and fostering consistency. Discover more in our latest article.

The Ultimate Guide To Sheet Metal Fabrication Design

Explore the essentials of sheet metal fabrication design with our ultimate guide. Whether you're starting a new project or enhancing your knowledge, this article offers valuable insights into metal types, fabrication techniques, and design considerations to ensure high-quality outcomes in diverse industries.

Powder Coating Texture Types

Discover the benefits of powder coating texture types like fine, rough, ripple, and hammered. Find out how to choose the right powder coating texture and how we can assist you.

What Is The Metal Forming Process?

In this article, we will delve into the world of metal forming processes. We will explore the various techniques, applications, and materials involved.

Importance of Precision in Sheet Metal Fabrication

Are you prepared to explore the significance of precision in sheet metal fabrication? Our article delves into the advantages of precision and the techniques and tools used to achieve precision in sheet metal fabrication.

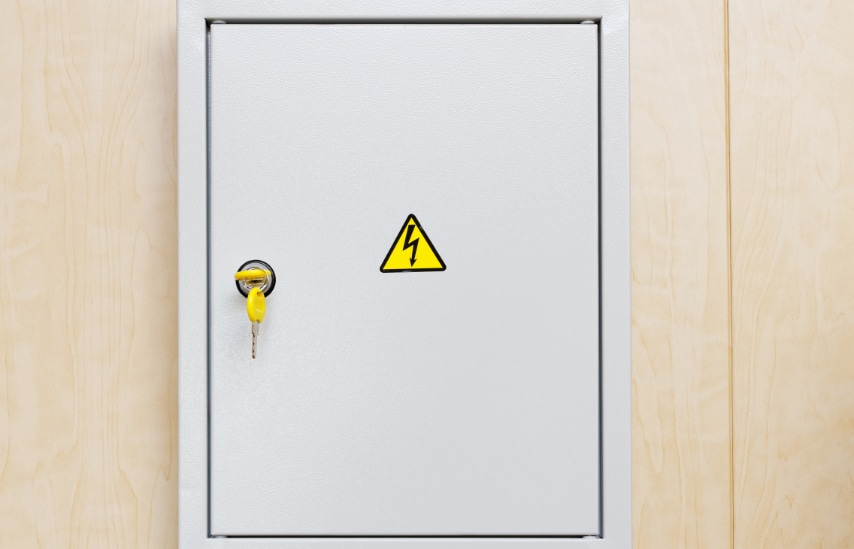

Do Electrical Enclosures Need Ventilation?

Discover the role of ventilation in electrical enclosures, ensuring their optimal performance and longevity. Learn why proper airflow is essential for preventing overheating and promoting system efficiency.

5 Benefits of Steel Electrical Enclosures

Learn about the benefits of steel electrical enclosures, including fire resistance, waterproof capabilities, long-lasting performance, and environmental friendliness. Discover why they are the ideal choice for various industries.

What Is The Steel Enclosure Manufacturing Process?

Discover the manufacturing process of steel enclosures in this insightful article. Gain a comprehensive understanding of the steps involved in creating steel enclosures and the types of steel you can use.

Metal Enclosure IP Ratings Explained

Discover the importance of IP Ratings for Metal Enclosures. Learn how these globally recognised standards safeguard electronic components from dust, water, and more. Make informed choices for your equipment's protection and longevity.

MIG Welding vs TIG: The Key Differences

Discover the Key Differences: MIG Welding vs. TIG Welding. Uncover which welding method suits your project best, from speed and ease of use to materials and precision. Make an informed choice for optimal results.

Sheet Metal Enclosure Design: Key Design Tips

Discover the essentials of Sheet Metal Enclosure Design: Learn about material selection, structural integrity, functionality, and thermal management to create reliable, protective enclosures. All these components come together to help us create you, durable and dependable protective enclosures for your specific requirements.