When laser cutting, there are many materials to choose from. From metals like stainless steel to delicate materials like leather and even alternative materials like glass, the options are vast. Each material brings its own set of challenges and benefits. Understanding the characteristics and requirements of each material can lead to a successful laser cutting/ fabrication project.

Metal

Metal materials, such as stainless steel, mild steel, aluminium, copper, and brass, are commonly used in laser cutting processes.

Each metal type requires specific laser settings and techniques for precise cutting results.

At Wrekin Sheetmetal, our laser cutting machines, including Amada LC F1 NT Series and VENTIS-AJ fibre laser cutter. They can cut metal with thicknesses between 8mm and 25mm, depending on the type of metal.

Aluminium

Aluminum is a commonly used material that is well-suited for laser cutting because of its versatility and reflective properties.

When cutting aluminium, fibre lasers are preferred due to the metal's reflective nature. The high power of fibre lasers allows for efficient cutting of this metal.

Aluminium's ability to be easily manipulated and its reflective surface make it an ideal choice for various laser-cutting applications. These applications include appliances, medical equipment, electronics, and more.

Steel (Stainless Steel and Mild Steel)

Cutting stainless steel and mild steel with laser technology is a common practice in metal fabrication due to its precision and versatility. Laser cutting offers high accuracy and intricate detailing on these metals.

Stainless steel is known for its corrosion resistance, making it ideal for various applications, such as cutlery, medical equipment, infrastructure (e.g.bridges) and more.

Mild steel, on the other hand, is cost-effective and widely used in industries like automotive and construction due to its strength and durability.

Copper

When considering materials suitable for laser cutting, copper stands out for its conductivity and malleability, making it a versatile choice for various applications.

Laser-cutting copper requires high power due to its thermal conductivity. The process can result in clean cuts with minimal burrs, offering precision and intricate detailing.

The reflective nature of copper may require changes in laser settings to ensure optimal cutting results.

Brass

Laser cutting brass demands careful consideration due to its unique properties and characteristics. Brass, a copper-zinc alloy, is suitable for laser cutting due to its thermal conductivity and malleability.

However, the reflective nature of brass can impact cutting quality- requiring precise laser settings. It's essential to use high-power lasers and proper ventilation when cutting brass to achieve clean and precise cuts without compromising the material's integrity.

Leather

Leather is a strong and flexible material that's effectively cut using CO2 lasers to achieve clean cuts while avoiding stress distortion. When laser cutting leather, the precision of the CO2 laser guarantees intricate designs and accurate cuts without compromising the material's flexibility.

This method allows for customisation in leather crafting, creating precise patterns for various products like wallets, belts, and accessories. The controlled heat application of the laser beam seals the edges of the leather, preventing fraying and maintaining durability.

Additionally, laser cutting leather offers a smooth finish without the need for post-processing, saving time and effort in production.

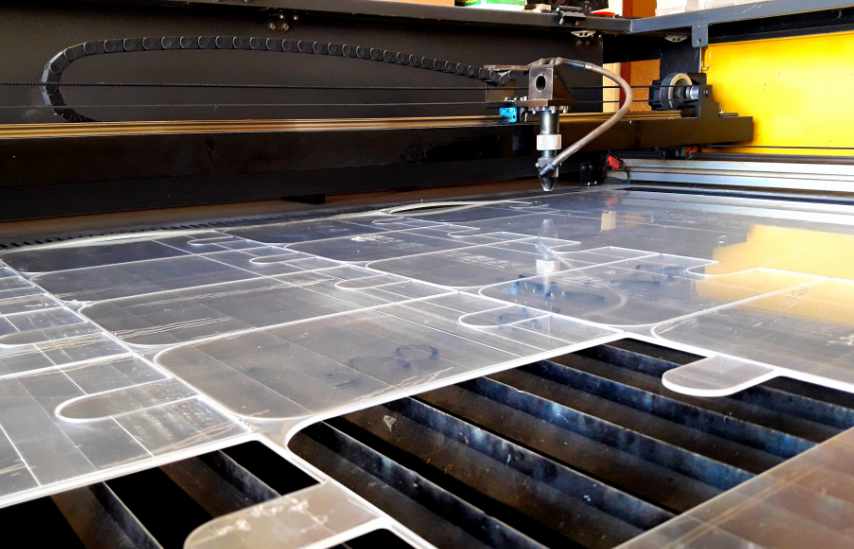

Acrylic

CO2 lasers are highly effective for cutting acrylic due to their transparent properties and optical clarity. Acrylic is a versatile material suitable for laser cutting. When using a laser cutter with the right settings, acrylic can be cut cleanly and precisely. It provides a polished finish and is commonly used for various applications like signage, displays, and artistic creations.

Ventilation is essential when laser cutting acrylic to prevent the release of harmful fumes. Proper laser power and speed settings are vital to avoid scorching the material. By following the recommended guidelines and using the appropriate laser equipment, you can achieve intricate and detailed cuts on acrylic with ease.

Wood

Wood stands out as a versatile option due to its widespread availability and adaptability to intricate designs. Different types of wood like plywood and MDF are commonly used for laser cutting due to their ease of workability.

When cutting wood, it's important to be cautious of oils or resin that may be present in the material to prevent fire hazards during the laser cutting process. Ventilation is necessary when working with wood to make sure the smoke and fumes are properly extracted from the cutting area. However, if you outsource your laser cutting to a specialist, this will not be a problem.

Additionally, adjusting the laser cutter settings such as power and speed is essential to achieve clean and precise cuts on wood materials. With the right precautions and settings, wood can be a fantastic choice for laser-cutting projects, offering endless design possibilities and a natural aesthetic.

Paper

Paper is an ideal material for laser cutting due to its versatility and suitability for intricate designs such as wedding invitations. When using a laser cutter on paper, make sure to use low power settings and high feed speeds for clean cuts.

Thicker papers may require lower feed rates to prevent burning or scorching. The precision of laser cutting allows for intricate patterns and detailed designs on paper, making it a popular choice for crafting and stationery.

Whether you're creating intricate lace-like patterns or precise text, paper is a versatile material that can be easily manipulated with a laser cutter. Remember to always work in a well-ventilated area when laser cutting paper to prevent any potential fire hazards.

Glass

Glass is a challenging material for laser cutting due to its fragility and reflectiveness. Its brittleness makes it prone to cracking under the intense heat of the laser beam. To successfully cut glass, high laser power is required along with a precise cooling system to manage the thermal stress and prevent unwanted fractures. Additionally, the reflective nature of glass poses a challenge as it can bounce the laser beam off the surface, affecting the cutting process

Plastic

Certain types of plastics can also be laser cut, though not all plastics are suitable. For instance, polypropylene and some other thermoplastics can be cut efficiently, whereas materials like PVC should be avoided due to the release of harmful fumes.

To conclude, a wide range of materials can be laser cut, including metals, leather, acrylic, wood, paper, and certain types of plastics. Each material offers unique properties and considerations for successful laser-cutting projects.

With 20 years of experience in the fabrication industry, Wrekin Sheetmetal specialises in end-to-end production. Our expertise lies in utilising sheet metal throughout our fabrication process, which includes laser cutting. We are capable of laser cutting various materials such as mild steel up to 25mm, stainless steel up to 20mm, aluminium up to 15mm, brass up to 10mm, and copper up to 8mm. Our team have extensive laser-cutting capabilities, click here to find out more.

How can we help?

With over 17+ years of knowledge and experience, we’re confident we can offer a flexible solution beneficial to both parties, get in touch with us today.