Are you curious about how steel enclosures are made? Whether you're an industry professional or simply interested in the process, this article will provide you with a clear understanding of how steel enclosures are manufactured.

Stainless Steel Enclosures

Stainless steel enclosures are commonly used in industrial applications due to their durability and resistance to corrosion. These enclosures provide a reliable and long-lasting solution for housing electrical components and protecting them from external elements.

The stainless steel material ensures that the enclosures can withstand harsh environments, including exposure to moisture, chemicals, and extreme temperatures. With their robust construction, stainless steel enclosures can endure heavy-duty use and maintain their structural integrity over time.

These enclosures are also easy to clean and maintain, making them an ideal choice for industries that require stringent hygiene standards. Whether it's in manufacturing plants, power generation facilities, or outdoor installations, stainless steel enclosures offer the strength and protection needed for reliable performance in industrial settings

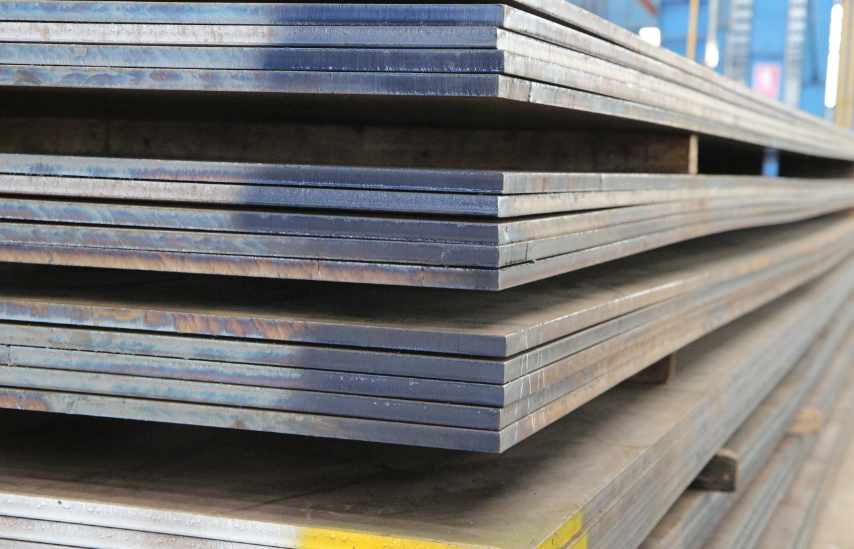

Mild Steel

Mild steel is a common material choice for creating sturdy and cost-effective enclosures. It is widely used in various industries due to its strength and affordability. When manufacturing mild steel enclosures, the process typically involves cutting, bending, and welding the steel sheets to create the desired shape and structure.

The mild steel sheets are easy to work with and can be customised to meet specific requirements. Additionally, mild steel enclosures can be finished with various coatings or paints to enhance their durability and aesthetics.

Mild steel is a reliable and practical choice for those seeking to create robust enclosures without breaking the bank.

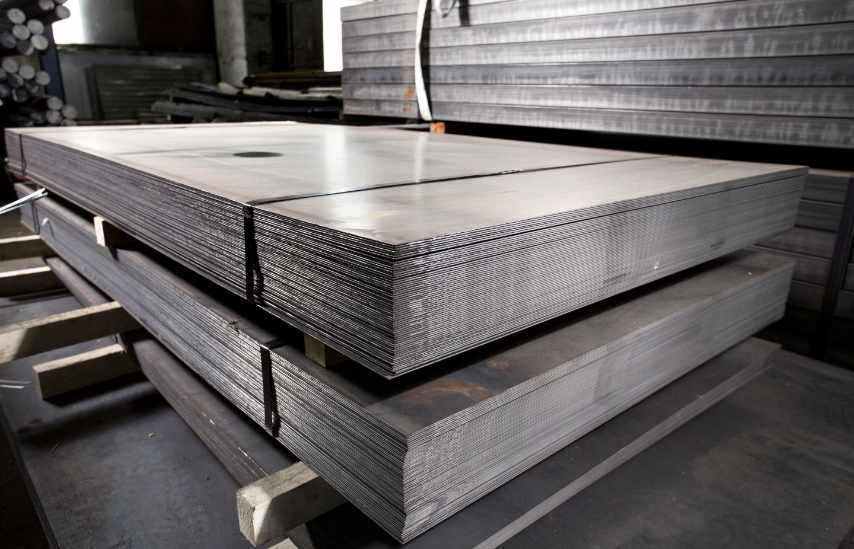

Galvanised Steel

If you're looking for a material that offers excellent corrosion resistance and durability, galvanised steel is a great choice for your electrical enclosures. Galvanised steel is steel that has been coated with a layer of zinc, which provides protection against rust and corrosion. This makes it ideal for enclosures that may be exposed to harsh environments or outdoor conditions.

The galvanisation process involves immersing the steel in a bath of molten zinc, allowing the zinc to bond to the surface of the steel. This creates a protective barrier that helps to extend the lifespan of the enclosure. Galvanised steel is also known for strength and it is a reliable option for protecting your electrical components.

Steel Enclosure Manufacturing Process

Enclosure Finishing

Powder coating is a popular finishing technique for achieving durability and aesthetics in electrical enclosures. It involves applying a dry powder to the surface of the enclosure and then curing it using heat or UV light.

This process creates a strong and durable finish that is resistant to chips, scratches, and corrosion. Powder coating also provides a smooth and uniform appearance, enhancing the overall aesthetics of the enclosure.

It is available in a wide range of colours and finishes, allowing for customisation to match specific design requirements. Additionally, powder coating is an environmentally friendly option as it produces minimal waste and does not emit volatile organic compounds (VOCs).

Overall, powder coating is a highly effective and efficient method for finishing electrical enclosures.

IP65 Testing

To ensure the durability and reliability of your electrical enclosures, it is important to conduct ingress protection testing.

IP65 testing is a crucial step in the manufacturing process that evaluates the enclosure's ability to withstand dust and water ingress. This testing is essential for various industries, including industrial and commercial applications.

Delivery & Installation

The delivery and installation of electrical enclosures can be arranged to ensure a seamless transition for your equipment.

Once the manufacturing process is complete, the enclosures will be carefully packaged and shipped to your desired location. Our team will work with you to coordinate the delivery, taking into consideration any specific requirements or time constraints you may have.

Upon arrival, our experienced technicians can handle the installation of the enclosures, ensuring they are properly positioned and securely mounted.

We understand the importance of a smooth and efficient installation process, as it directly impacts the functionality and safety of your equipment.

In conclusion, the process of manufacturing steel enclosures involves several important steps. Each step, from determining specifications to fabricating and assembling the enclosure, requires careful consideration and expertise. Factors such as material selection, fabrication methods, and finishing techniques all play a crucial role in creating high-quality enclosures.

Here at Wrekin Sheetmetal, we can manufacture your custom-designed enclosures.

How can we help?

With over 17+ years of knowledge and experience, we’re confident we can offer a flexible solution beneficial to both parties, get in touch with us today.