Metal enclosures are solid metal cases that are manufactured to suit a particular purpose. It is primarily designed to protect critical components.

Considerations for Material Selection

When constructing a sheet metal enclosure, you have a lot of materials to choose from. Some of the most common ones can be found below.

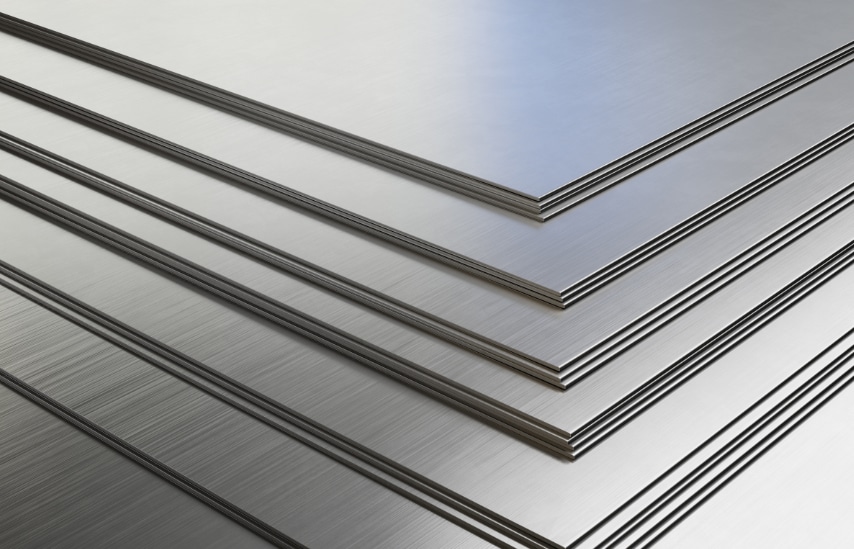

Stainless Steel

Stainless steel enclosures not only provide a very high level of protection against corrosion, but they also help to limit heat damage as well as chemical damage. Their polished appearance makes them very pleasing to the eye, so they are especially suited to commercial or industrial applications.

Mild Steel

Steel enclosures tend to be resistant to pests, fire and even corrosion. Enclosures that are made out of mild steel are able to withstand environmental conditions that range from excessive heat to extreme cold. Mild steel enclosures offer more protection when powder coated.

Galvanised Zinc Coated Steel

Galvanised zinc-coated steel acts as a barrier to the elements. It is long-lasting and high in quality. It is able to offer increased strength and durability, not to mention that it is very formidable. This makes it one of the most popular material choices for metal fabrication.

Aluminium

Aluminium is incredibly rugged and it has a high tensile strength. It is resistant to corrosion and very lightweight. Radio waves can be blocked and electromagnetic wavelengths can be reflected when aluminium is used as a barrier.

When exposed to water and oxygen, aluminium will quickly corrode unless it has been anodised. Rest assured that here at Wrekin Sheetmetal, we offer a range of specialist finishing services, including anodising.

Factors to Consider when Selecting a Material

There are many factors to think about when choosing a material for metal enclosures. Some of them can be found below.

Strength and Durability

If the enclosure is going to be used within a high-intensity environment then you have to make sure that it can withstand the external environment.

Cost and Availability

If you want to get a solid enclosure on a budget, then aluminium and stainless steel are very good choices. If there is a shortage of a particular type of metal then your enclosure will take longer to make. Mild steel is the cheaper option on most occasions.

Aesthetic Appeal

All of the materials mentioned have a high standard of aesthetic appeal, meaning that it doesn’t matter which one you opt for because they will all look professional when used for any application.

Corrosion Resistance

Stainless steel, copper, brass, bronze, aluminium and galvanised steel are all highly resistant to corrosion. If you intend on housing your metal enclosure outside, then it is imperative to choose a material that can withstand the elements. If your enclosure isn’t resistant to corrosion, you will have to replace it more often.

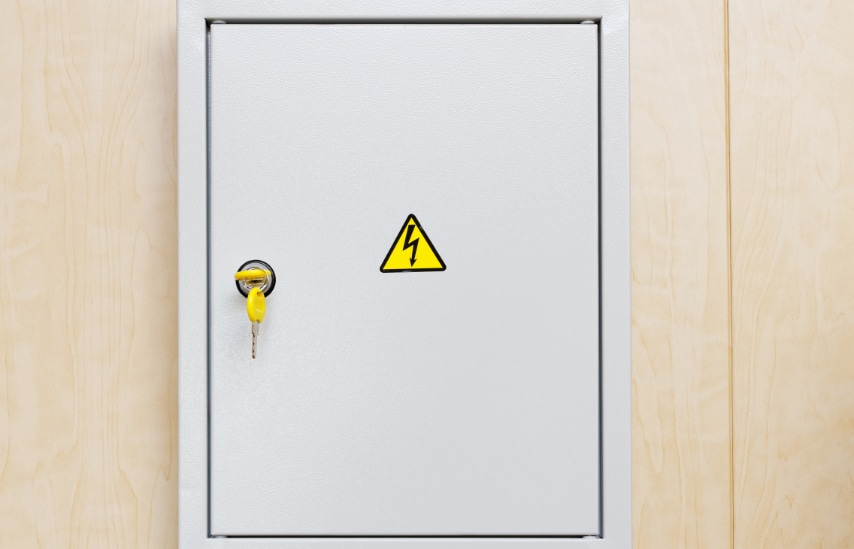

Remember, you need to be careful of some metals and coatings in your enclosures that are used for electrical installations.

Emphasising Structural Integrity

When determining structural integrity, the first thing you need to do is take into account the design. Some designs are more secure than others, but as a result, they may be heavier, cost more or use less accessible materials. The bonding process also helps to ensure structural integrity.

Welding

Welding creates a joint between two parts. This is often where two sheets of metal connect. Although different welding techniques often result in different types of joints, it’s important to know that strong joints make robust and durable products. Welded joints are ideal if you want your enclosure to be leak-proof.

Adhesive Bonding

Adhesives can also be used to bond two surfaces together. The one benefit of doing this is that it helps to seal out moisture. It also locks out dirt and other contaminants. As adhesive bonding creates a solid bond, there is no need to add mechanical fastenings.

Mechanical Fastenings

Another option would be mechanical fastenings. This is a tried-and-tested method of bonding. Mechanical fastenings are very simple to install and they can be put to use right away with no cure time. There is very little mess involved as well.

Designing for Functionality

When working on a sheet metal enclosure design, you need to make sure that you keep functionality in mind. Understanding the product requirements is crucial, because if the case cannot be accessed with ease, then it may protect the contents, but it will be an inconvenience to everyone who needs to use it.

Features and functions also need to be considered. This could include the opening mechanism, closing mechanism, whether it can be locked and more.

Ventilation and Heat Dissipation

Some products require heat dissipation and ventilation. It’s vital to consider environmental conditions such as this when constructing your metal enclosure, because if you don’t then it could lead to dangerous accidents in the future.

Access Points

If the contents need to be maintained, then they should be easy to access. If not, the enclosure has to be sealed so that no contaminants can get in.

Addressing Environmental Conditions

It’s so important that you design your enclosure so that it is able to withstand external elements.

Considering Ingress Protection (IP Ratings)

IP stands for Ingress Protection. It is often found in the form of a table. The IP rating is a measure of an enclosure’s ability to resist anything that enters it. It could be a large item, such as someone’s hand, or something small, such as a speck of dust, or a drip of water. Here at Wrekin Sheetmetal all of the metal enclosures we manufacture are IP65-rated.

Incorporating Sealing Techniques

Ensuring proper protection for the contents of the enclosure is so important. If dust, insects and water cannot get in, then there will be no contamination.

Designing for Thermal Management

If there are electronics within the enclosure, then it is so important to make sure that the contents don’t heat up over time.

Heat Dissipation

Sometimes, mechanisms can be added to ensure adequate heat dissipation. A good example here would be the fans within a laptop, or in computer equipment. Fan housings are used within the design.

So there are many key design elements to choose from when choosing an enclosure. This includes the materials used, access to the enclosure and even thermal management. Here at Wrekin Sheetmetal, our team can offer their expertise and we can help you design and manufacture your metal enclosures. Take a look at our metal enclosure page to see our steel enclosure manufacturing process.

How can we help?

With over 17+ years of knowledge and experience, we’re confident we can offer a flexible solution beneficial to both parties, get in touch with us today.